how does a universal testing machine generate force|universal testing machine load cell : specialty store marked a major milestone with the integration of computers into UTMs. This led to digital control and data acquisition, automating testing procedures and enhancing the precision a

Resultado da 11/11/2023 às 06:00. São Paulo, SP. Enquanto o Grêmio briga pela liderança do Campeonato Brasileiro, o Corinthians luta para se afastar da zona de .

{plog:ftitle_list}

web162K Followers, 39 Following, 62 Posts - See Instagram photos and videos from Anna Vlasova (@anna_vlasovaofficial)

A Universal testing machine (UTM) is used to test the mechanical properties (tension, compression etc.) of a given test specimen by exerting tensile, .An electromechanical UTM utilizes an electric motor to apply a controlled force, while a hydraulic UTM uses hydraulic systems for force application. Electromechanical UTMs are favored for their precision, speed, and ease of use, making them suitable for a wide range of applications, including tensile, compression, and flexural testing. On the other hand, hydraulic UTMs are capable of generating higher forces and are often used f.Engineers apply the knowledge of math & science to design and manufacture maintainable systems used to solve specific problems. AskEngineers is a forum for questions about the technologies, standards, and processes used to design & build these systems, as well as for questions about the engineering profession and its many disciplines. A hydraulic press is a machine press using a hydraulic cylinder to generate a compressive force.It uses the hydraulic equivalent of a mechanical lever, and was also known as a Bramah press after the inventor, Joseph Bramah, of England.He invented and was issued a patent on this press in 1795. As Bramah (who is also known for his development of the flush .

Many different types of testing profiles can be used to test a syringe. There are ASTM and ISO standards, for example, ISO7864 and ISO9626, ISO7886, ISO8537 as well as individual company specified testing profiles. You may .

marked a major milestone with the integration of computers into UTMs. This led to digital control and data acquisition, automating testing procedures and enhancing the precision a

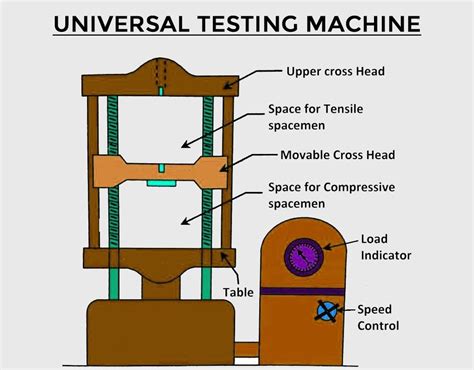

A universal testing machine consists of two main parts : Loading Unit; Control Unit; The arrangement of the test specimen and the exertion of the load is held in the loading unit.The variations in the application of the load and the corresponding test result are obtained from the control unit.. In the figure-2, the left unit with table and crosshead form the loading unit.

is used to test the mechanical properties (tension, compression etc.) of a given test specimen by exerting tensile, compressive, or transverse stresses. The machine has been namedUniversal Testing Machine is used for evaluating the mechanical characteristics of materials by subjecting them to different tests, such as tensile, compression, flexural, shear, hardness, and torsion testing, providing valuable data for designing and ensuring the quality of materials in applications across various industries, from manufacturing to research and development.

Key Components of a Universal Testing Machine. To understand how a universal testing machine operates, we first need to become familiar with its key components. The main components are as follows: 1. Load Frame. The load frame provides the UTM's structural backbone. It houses all the moving parts and provides machine stability during testing.Tensile testing on a coir composite. Specimen size is not to standard (Instron). Tensile testing, also known as tension testing, [1] is a fundamental materials science and engineering test in which a sample is subjected to a controlled tension until failure. Properties that are directly measured via a tensile test are ultimate tensile strength, breaking strength, maximum .

The Servotec Low-Force Series Single Column Universal Testing Machine can perform various types of mechanical tests, including tensile strength (pulling), compression strength (pushing), bending, adhesion (peel) and flexural strength tests.Single-column systems are often preferred for smaller sample sizes or lower force requirements due to their cost-saving and compact design .

ASTM E4 for example, specifies the procedure for calibrating tension and compression force generation in a Universal Testing Machine. Since force is a vector, ASTM E4 includes details like the correct location of connection points to the load and the resultant magnitude and direction of the forces to be applied. ASTM E4 requires two runs of . What it takes to calibrate a Universal Testing Machine in North American. The Do's and Do nots of finding the right ISO 17025 calibration laboratory. Home; Products. Special Offers. . NG-SHM Class A – Servo Hydraulic Testing Machine – force capacity range from 200kN to 3000kN. Load frame configurations are servo-controlled hydraulic and 4 .Máy kiểm tra đa năng Universal Testing Machine Hans-Schmidt Viet Nam . Force-Displacement Measuring System FSA. Capacity: Max. 2500 N; Motorized- and adjusting knob operation; . Software to generate force-distance graphs; User programable travel distance with mechanical adjustable limits . Máy kiểm tra đa năng Universal Testing Machine.

The main components of a universal tensile testing machine include: Load Frame: The load frame is the main structure of the testing machine and provides the framework fThus, we at Testronix Testing Instruments have designed high-quality lab testing equipment known as a universal testing machine. This universal tensile strength tester is one of the high-quality lab testing equipment that will .Universal Testing Machine with TestWise™ software, available in 5 kN, 10 kN and 25 kN capacity models. A universal strength tester suitable for testing a diverse range of applications - including apparel, nonwovens, and other non .

Available Model As per suitable Products & Application Range. UNIVERSAL TENSILE TESTER SDTRX-10KN - Suitable for Fabric, TAPE, Yarn & HDPE pipe samples. 10.3.1 Material. In this study, the material being tested is a Dual Phase (DP) grade steel with a UTS of 1000 MPa or commercially known as DP1000. Mechanical properties of the DP steel can be found in Table 10.1.The suitable way to test this DP sheet-type steel is by using the 12.5 mm width geometry according to the ASTM Standard E8/E8M Standard Test .Hydraulic Universal Test Machine. HUD-B616. LET US HELP YOU. Let’s Talk. Contact Us; HUDA---Win the trust of the global market with technical strength and local service. Follow Us: Contact Us. No. 02, Lida Road, Changchun Economic Development Zone, Ziyang District, Yiyang City,Hunan Province, China. Phone: 86-769-89201493 / 86-134 5005 4137 .The CS2Plus is a high-precision, digital force testing machine designed to streamline testing workflows in production and laboratory environments. Suitable for testing applications up to 5 kN (1100 lbf), it excels in material testing across various industries, including: • Plastics • Rubber • Packaging • Pharmaceuticals • Cosmetics .

3. INTRODUCTION A universal testing machine, also known as a universal tester, materials testing machine or materials test frame, is used to test the tensile stress and compressive strength of materials. It is named after the fact that it can perform many standard tensile and compression tests on materials, components, and structures.The functionality and precision of the UTM largely depend on its design and the different components used in its making. It is needless to say, the Best Computerized Universal Testing Machine will provide the best results due to the precision and perfect harmony in the operation of the different components in the machine.. Each component in a UTM plays a significant role, .1.3.2. On Test Control > Pre-Test, enable Preload and apply a small preload to ensure that there is no slack in the specimen. Preload value should be lower than preload used in method used to test specimens. 1.3.3. On Test Control > End of Test, set the end of test criteria to a force higher than expected in a real test, but lowerUniversal Testing Machine. The Universal Testing Machine, also known as the Tensile Testing Machine, serves as a versatile tool capable of conducting tests on a wide range of materials.These materials encompass metals, concrete, rubbers, fabrics, vegetables, and many others, making it possible to assess the properties and characteristics of virtually any material.

Surprisingly, the answer is positive, as it will be shown in this work. This breakthrough result can be obtained by estimating the translational and rotational accelerations of dynamometer base by means of dedicated accelerometers, and then by reconstructing the input forces from the combination of force and acceleration signals, through the new, non . The Universal Testing Machine (UTM) is an indispensable tool in the realms of material science and engineering, widely employed for evaluating the physical . test type, and expected force range. Initiate the Test: Once all settings are confirmed, start the test. The UTM will apply the specified force to the specimen while collecting data on .

This test is performed on a universal testing machine (tensile testing machine or tensile tester) with a 3 point or 4 point bend fixture. . Flexural Strength – This measures the maximum force that a material with withstand before it breaks or yields. Yield is where you have pushed a material past its recoverable deformation and it will no .

refractometer hand held

The official website for Lynn Johnston's For Better or For Wor.

how does a universal testing machine generate force|universal testing machine load cell